DTF (Direct to Fabric) printing is a cutting-edge apparel production technique, offering simple, cost-effective customization for businesses and individuals. Its key advantages are small batch sizes, on-demand printing, and vibrant color accuracy on light fabrics without complex setup. This method supports various materials and print areas, ensuring high-quality, visually appealing garments. Optimizing results requires careful ink and substrate selection, proper pre-treatment of light fabrics, precise design preparation for crisp transfers, and thorough post-printing care to preserve colorfastness.

“Discover the revolution in textile printing with DTF (Direct-to-Garment) technology, tailored for light-colored garment materials. This article explores the advantages of DTF for achieving vibrant, long-lasting designs on lighter fabrics. We’ll guide you through the process, from understanding DTF Printing to choosing the right inks and substrates, pre-treating fabric, design considerations, and post-printing care. Optimize your printing techniques and elevate the quality of your light-colored garment creations.”

- Understanding DTF Printing: A Direct-to-Garment Approach

- Advantages of DTF for Light-Colored Garments

- Choosing the Right Ink and Substrates for Optimal Results

- Pre-Treatment: Preparing Your Light-Colored Fabric

- Design Considerations for Effective Image Transfer

- Post-Printing Steps to Ensure Longevity and Quality

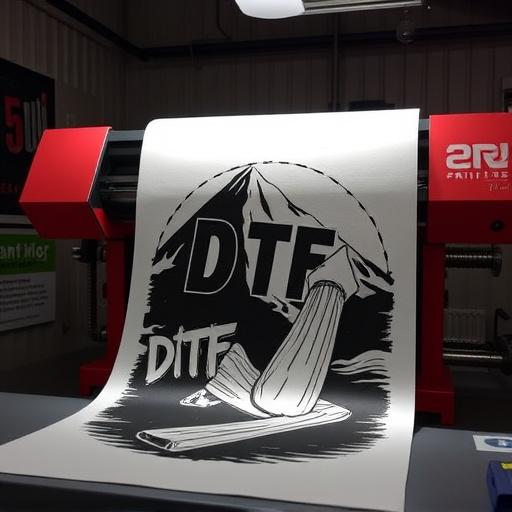

Understanding DTF Printing: A Direct-to-Garment Approach

Direct-to-garment (DTF) printing is a cutting-edge technique revolutionizing the apparel industry. Unlike traditional methods that often require intricate setup and multiple steps, DTF offers a straightforward approach to applying designs directly onto light-colored garment materials. This modern method involves transferring ink from a print head to the fabric surface, creating vibrant, high-quality prints with minimal effort.

DTF Printing is particularly advantageous for small-batch production and on-demand printing, making it an attractive option for businesses and individuals looking to create unique, personalized garments. By eliminating the need for costly plate preparation and complex machinery, DTF enables efficient and cost-effective customization of light-colored fabrics, ensuring that each piece stands out with its own distinct design.

Advantages of DTF for Light-Colored Garments

Direct to Fabric (DTF) printing offers several advantages for light-colored garment materials, making it a preferred method in the industry. One significant benefit is its ability to produce vibrant and accurate colors on lighter fabrics without the need for complex preparation or finishing processes. This direct approach ensures that the design’s original intent is maintained, resulting in an exceptional visual impact.

Additionally, DTF technology provides excellent versatility in terms of material types and print areas. It can be applied to various light-colored fabrics, including cotton, linen, and certain synthetic blends, allowing designers and manufacturers to create a wide range of apparel and accessories. This versatility, combined with the high-quality prints, makes DTF Printing an attractive choice for those seeking to produce unique and visually appealing garments.

Choosing the Right Ink and Substrates for Optimal Results

When optimizing transfers for light-colored garment materials, selecting the appropriate ink and substrates is paramount to achieving superior results with DTF (Direct to Fabric) Printing. Light colors can sometimes require specialized inks that offer higher opacity to ensure the design stands out clearly. Pigment-based inks are often recommended due to their ability to cover lighter fabrics effectively without fading or losing vibrancy. Additionally, choosing the right substrate is crucial; a blend of polyester and cotton, for instance, offers both durability and breathability, ideal for creating transfers that adhere well and last longer on various garments.

The compatibility between ink and fabric also plays a significant role. Some inks might be formulated to bond better with specific fabrics, so testing different combinations is advisable. Moreover, considering the care instructions of the final products ensures customer satisfaction; proper material selection can dictate whether the transfers will withstand machine washing or are best hand-washed, influencing the overall customer experience and the longevity of the garments.

Pre-Treatment: Preparing Your Light-Colored Fabric

Before applying transfers to light-colored garment materials, proper pre-treatment is crucial to ensure optimal results with DTF (Direct to Fabric) Printing. Start by gently cleaning the fabric to remove any dirt, oils, or finishes that could interfere with ink adhesion. A mild detergent and warm water are usually sufficient for this step. Avoid using harsh chemicals or bleach, as they may damage the fabric fibers.

Once cleaned, it’s essential to prepare the fabric’s surface. This might involve light sanding or using a fabric prep solution to create a slightly rough texture, which aids in ink penetration. Be sure to follow the manufacturer’s instructions for any prep solutions to ensure safe and effective use. Proper pre-treatment significantly enhances the durability and vibrancy of the final print on light-colored fabrics.

Design Considerations for Effective Image Transfer

When designing for DTF (Direct-to-Fabric) Printing, a key focus is achieving crisp and vibrant image transfers on light-colored garments. The initial design considerations revolve around file preparation and resolution. High-resolution digital art with clean lines and sharp details ensures optimal print quality. Using vector graphics or properly optimized raster images minimizes potential pixelation or blurriness during the transfer process.

Additionally, color selection plays a crucial role. For light-colored fabrics, it’s essential to reverse out designs (white text/objects on a dark background) to avoid blending with the fabric. This ensures contrast and clarity in the final print. Further, designing with the specific garment material in mind is vital; for instance, considering fabric texture or surface treatment can impact ink adhesion and overall transfer effectiveness.

Post-Printing Steps to Ensure Longevity and Quality

After the DTF (Direct to Fabric) printing process, several post-printing steps are crucial to ensure the longevity and quality of designs on light-colored garment materials. The first step is to allow the ink to cure completely. This usually involves drying the printed garments at a specific temperature for a recommended duration, as indicated by the printer’s instructions. Inadequate curing can lead to smudging or fading over time.

Next, it’s essential to perform a quality check to identify any print defects like misalignments, ink bleeding, or uneven colors. Minor issues can often be addressed by lightly pressing the garment between sheets of paper to absorb excess ink and prevent transfer to other items. For more significant problems, it might be necessary to re-print the design. Finally, washing instructions should be followed carefully to maintain the vibrancy of colors and prevent shrinkage or color run, especially for delicate fabrics. Proper care will ensure that printed garments retain their aesthetic appeal and functionality for extended periods.